Chapter CL: The Murky Depths of Black Gold

Chapter CL: The Murky Depths of Black Gold.

The issue of whether a barrel of crude oil was fungible was not the sort of question that most politicians or senior civil servants bothered themselves with, and not just because they may not have been able to understand it. For those that did the answer would undoubtedly be yes it was fungible, from the grand strategic perspective it was merely important to have a reliable supply of "oil" (whether from domestic production or secure sources of import) and no real distinction was made as to the type. However if you ran a refinery then oil was very much not fungible, a barrel of sweet and light Iraqi crude could not usefully be substituted for by any amount of Venezuelan sour and heavy oil, at least not if you wanted the refinery to run properly. So those inside the oil market made sure to be careful in their negotiations and specifications, preferring to trade directly with the oil producers to be surer of exactly what they were buying. Hence while one could find a quoted "price" for a barrel of oil it was at best an indicative reference, one calculated as the average from many wells of varying quality. The price you would actually pay could vary considerably, depending if one wanted a higher quality or could find a use for the dregs the supplier was keen to be rid off. These two worlds would happily have co-existed without ever crossing over, or even being particularly aware of each other, had a technological development not intervened and forced the strategists to engage with the practical realities. The prompt for this was the seemingly minor decision of the RAF to switch from 87 octane fuel to 100 octane, to take advantage of the greater 'anti-knock' properties of that fuel and the resulting further boost to aero-engine performance. The service had only finally completed switching from 77 to 87 octane in 1935 so there was a degree of grumbling from the Treasury at another change so soon, however as fuel was always being used up (and indeed could 'spoil' if left too long) it was expected this could be managed with minimal wastage of existing supplies and some fairly cheap alterations to existing engines. The Air Ministry obtained some samples of 100 octane fuel from Royal Dutch Shell's US subsidiary at the start of 1936 and began testing. At this point the problem emerged; none of the fuels worked as promised and in many cases performance decreased or the engine itself suffered damage. With the start of the Abyssinian War the issue dropped to a low priority and was kicked out to a research group run by the Royal Aircraft Establishment and experts from the fuel and engine industry. By the end of 1936 the Air Ministry was paying attention again and the group reported back, their first finding being that the Octane Number was a terrible way to classify fuels, a fact long suspected even by those who had invented the system. The trials demonstrated it was possible to produce completely different mixtures that had very different effects on an engine and get both of them to test as '100 Octane'. To briefly explain the octane number was a rating of the fuels ability to resist detonation, that is the fuel in the cylinder combusting at the wrong time due to ambient heat or pressure and not because of the spark from the sparkplug. If the fuel did detonate too early that caused a dramatic pressure increase in the affected cylinder that could damage the engine, it also made a very distinctive 'knocking' sound, hence why higher octane fuels were said to have 'anti-knock' properties. A fuel that was more resistant to knock meant an engine could run a higher manifold pressure, which meant more fuel and air being combusted and so more power produced, assuming of course that the rest of the engine could handle the higher pressures.

The group further proved that the octane number of any individual fuel could vary with the fuel-air mix inside the cylinder, but that this change depended upon the composition of the fuel. This was a problem as British military engines had developed to take advantage of this fact, even if neither the designers or the Air Ministry had been consciously aware of it. British engines expected fuels which showed a 'rich mixture response', that is to say if you ran them at a rich mixture (more fuel than required) they would combust at a cooler temperature, which allowed you to run at a higher pressure and get more power, at the cost of increased fuel consumption. The Merlin in a Spitfire for instance could run at a rich mixture for take off and climb, then switch to a lean mixture for cruising at altitude to get the best of both. The problem was the US Army Air Corps (USAAC) had specified a maximum of 2% aromatics in their fuel, because above that content the aromatics started eating the fuel lines and damaging the engines, so the 100 Octane mixes they had developed followed that rule. In contrast the Air Ministry had a de-facto minimum aromatic content of 20% (their 77 octane fuel had in fact been called 80/20 as it was 80% aviation spirit and 20% aromatic benzol) and while this meant British aircraft needed stronger fuel lines to resist the corrosive effects this aromatic content was vital to get the 'rich mixture' response. The results was that if you tried to run USAAC 100 octane in a British engine you either had less power at take off and climb or you boosted the mixture as normal, didn't get the expected cooling effect, and so seriously damaged the engine due to excess knock. Fortunately the group's final finding was much more positive, they had developed a British blend of 100 octane, it would come to be known as BAM100 (British Air Ministry 100 octane), which had the required properties and then tested it in a Merlin. With minimal modification this allowed the supercharger boost of the engine to be increased from 6.25 psi to 12psi, if only for 5 minutes or so, but that extra boost equated to 300hp extra and was enough to give a Spitfire an additional 25mph at sea level, 35mph at 10,000ft and faster climbing at all altitudes. Rolls Royce were also confident they could strengthen the relevant parts of the Merlin and have the next models operating at 12psi boost at all times, with similar benefits expected in all future engines. This was clearly a valuable improvement and so the Air Ministry began making plans to start the changeover of existing designs and incorporate a requirement for BAM100 octane fuel into the new specifications and engine development plans. By this time news had filtered up to the Committee of Imperial Defence (CID) and the Oil Board became officially aware of the plans, those bodies raised concerns about the strategic implications of this plan, focusing on the issue of where the RAF proposed to get this new 100 octane fuel from and how supplies could be secured.

A Bristol Blenheim Mk.I bomber of No.90 Squadron being inspected by it's new crew at RAF Bicester. The squadron would be selected as one of the trials units for 100 octane fuel, Strike Command were keen to see what performance gains were possible for their bombers and so 'volunteered' the newly formed squadron. In the event the trials merely proved that not all existing engines would benefit from the new fuel; the Mercury VIII engines in the Blenheim were pressure limited not knock limited, so any attempt to increase boost risked damage to the engine. Bristol would strengthen the crankshaft and bearings of the design and produce the Mercury XV which could take roughly double the boost (+5psi to +9psi) and so eke the engines take off power up to 920hp as against the 840hp of the Mercury VIII. The resulting Blenheim Mk.IV had fairly similar performance, but with the extra take-off power available could carry more fuel and gained 300miles of range or carry more bombs to the same range. These gains were more typical of what could be expected from the change of fuel, very few existing engine/aircraft combinations would see the immense improvements that the Merlin powered Spitfires did.

The Oil Board was a sub-committee of the CID and as one would guess it was concerned with the supply and distribution of oil and all related fuels and substances. By the mid 1930s the glass, or perhaps the barrel, was either mostly full or basically empty depending upon how you looked at it. The negative case was that just over 5% of the oil imported into Britain came from the Empire, mostly the fields of Trinidad, and there was little prospect of that figure improving in the short or medium term. The positive case was that over 85% came from oilfields that were leased and operated by British companies (if one counted the Anglo-Dutch Shell concern as 'British) and from countries either within the Sterling Area or that accepted payment in sterling. The Oil Board tended towards the 'mostly full' interpretation and were of the opinion that the main limitation stopping that figure increasing was not actually supply or currency, but tanker capacity. This 'mostly full' position was not an accident, concerted efforts had been made to reduce dependence on US sources ever since the Board had been founded in the early 1920s and these had only accelerated after President Landon's policy choices during the ongoing war in Spain. The US and Britain ending up on opposite sides of that conflict, even if the US government strenuously denied that they had taken a side at all, had once again highlighted the risks of being dependent on US supplies in time of war. This background informed how they approached the question of 100 octane supply; Empire or Sterling Area production was preferred, avoid American sources if at all possible and make sure the impact on the tanker fleet was manageable. It should therefore be no surprise that Oil Board was quietly pleased that the existing US sources of high octane fuel were not suitable for RAF use and that they had got involved before a decision had been made. The board moved quickly to heavily recommended against the interim solution proposed by some of the oil companies of upgrading the US refineries used to make USAAC grade fuel to be able to produce BAM100 as well (only after long term supply contracts had been signed of course). This intervention very much cut to the heart of the matter, that while there was an official pretence that the matter was a private sector decision with the government 'just' buying the fuel, in reality there were no large customers for high octane fuel outside of military air forces, so the Air Ministry for once had a great deal of leverage. The subsequent question of where the fuel should be sourced from instead was more complex as many of the key considerations were impossible to know with any certainty. The key variables were where any future conflict would be fought and if the Mediterranean would be 'open' or 'closed' to tanker traffic. For planning purposes the answer on the former was decreed to be 'anywhere', while the most likely flashpoint was still see as a 'Far Eastern defensive operation' (code for war with Japan), the experience of the Abyssinian War had left the CID reluctant to rule anything out so options were prepared for a range of conflicts. They did however commit to the Med always being 'open', with the Italian fleet crippled and Mussolini focusing on rebuilding his land and air forces it was believed that the Med could be kept open to critical tanker convoys in any future conflict.

HMCS St Laurent, formerly the C-class destroyer HMS Cygnet she had been purchased by the Canadian government as part of their post-Abyssinian naval rearmament. In the summer of 1937 the St Laurent was serving with the Royal Navy's North America and West Indies Station, a secondment which had been seen as a low risk way for the Royal Canadian Navy to get some operational experience without the cost of going to Singapore or the political issues of the Spanish Civil War. An emergency call from the Governor of Trinidad for Admiralty assistance would shatter this belief and the St Laurent would be dragged into the Trinidad Oil Field Strike as she dashed to the islands alongside the cruiser HMS Ajax. A strike over low pay had been hijacked and turned violent, so the Royal Marine detachments of Ajax along side a 'landing party' from St Laurent would bolster the police until order was restored and the strike could play out peacefully. This was not the sort of experience Ottawa had envisaged it's sailors gaining and there was unease at being dragged into such affairs, yet there was also pride at how well the matter was handled, acknowledgment of the importance of Trinidad to the oil economy of the Empire and recognition of the fact that great engagement with affairs outside of Canada would inevitably result in more of these sort of incidents.

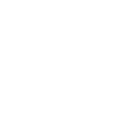

The final plan therefore spread it's bets somewhat, which was inline with the Air Ministry preferred portfolio approach and a practical necessity given the projected fuel requirements far exceeded what any one site could realistically produce. In the UK a single existing refinery, the Stanlow Refinery at Ellesmere Port, was selected for upgrades on the basis it dealt with the right sort of crude already, had direct access to the Atlantic shipping routes and was considered safely out of range of bombing raids from the continent. It was complemented by a new build site at Heysham in Lancashire which had similar logistical and strategic advantages, the extra cost of building a whole new refinery being believed to be a price worth paying to avoid the more vulnerable south coast refineries and to get the extra efficiences of a fully dedicated modern facility. A The second set of sites were in the West Indies, two of the Trinidad refineries would be upgraded as would the two large refineries in Curaco and Aruba, the later two being in the Dutch Caribbean but were owned and operated by Shell. These sites were close to the vast Venezuelan crude oil deposits that were rich in the aromatics that BAM100 needed, additionally the Venezuelan fields were majority controlled by British oil firms and the oil could be paid for in Sterling, ticking all the Oil Board boxes. Strategically these refineries were considered safely out of range of any potential enemy and based on the Great War and Abyssinian War experience Shell could be relied upon to support any British war effort even if the Netherlands stayed neutral. In the Middle East the vast Abadan refinery in Iran was selected, strategically it was the 'swing' site, while not especially well positioned for either Far Eastern or UK supply it was able to supply both as well as the local demands from RAF Middle East Command and the Mediterranean squadrons of the Fleet Air Arm. Abadan's true value would come from the experimental work being done there by the Anglo-Iranian Oil Company, it would be the Abadan pilot plant that would first produce 100 octane fuel by Alkylation. Without going into the detailed chemistry the key ingredient of 100 octane fuel, of any type, was iso-octane, up to this point it had been produced by a complex two stage polymerisation and hydrogenation process invented by Shell in the early 1930s. The Alkylation process that had been (accidentally) discovered by Anglo-Iranian's Sunbury laboratory was a single stage process that did not require the high temperatures and pressures of the Shell method, making it far faster and cheaper. The first large scale pilot plant for this process would be built at Abadan and it was there that it was refined from a lab bench idea to an industrial manufacturing process, by the end of the decade it would be the standard method for making iso-octane. The final set of upgraded refineries were in the Far East and were a matter of some debate, broadly the choices were the East Indies or Burma. Burma, specifically the large Burmah Oil refinery at Rangoon, was naturally preferred as being on British territory and being in a more secure location strategically, however it required the most work as it had been built to refine the light sweet Assam crude which was not an ideal feedstock for making 100 octane fuel. The East Indies options were supplied with the heavier and more aromatic Borneo crudes which were very suitable for high octane fuel, but were also right in the line of any hypothetical Japanese attack. In the end the Rangoon Refinery was too small and would need too much work, so the choice was made to go with an East Indies location. The refineries of Miri and Lutong were initially favoured as being almost on British territory, the exact status of the always unusual Raj of Sarawak being a tale of itself, however they dismissed as the North Borneo coast was just too vulnerable. The choice therefore settled on the large Shell refinery at Palembang, on the basis that if Java had fallen into enemy hands then any defence of the Far East probably had bigger problems.

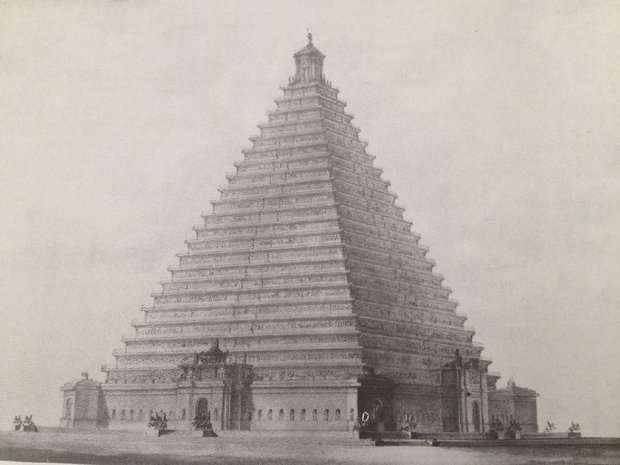

The Portsdown No.1 oil well, one of the first very deep level oil wells sunk in the British Isles, Portsmouth Harbour just visible in the background. The D'Arcy Exploration company (a subsidiary of Anglo-Iranian Oil) spent the mid and late 1930s carrying out a moderate investigation campaign within the UK, as part of a government supported imitative to find domestic sources of oil. While Portsdown would be a dud, by the summer of 1937 their attention have moved to Nottinghamshire were the geological team had discovered the first signs of the Eakring/Dukes Wood oilfield. While this would eventually become the UK's first commercial oil field it would never produce a significant amount of oil, joining the Scottish Shale Oil fields as such small scale producers that the Oil Board regularly forgot they even existed.

While this agreement between the CID, Oil Board and Air Ministry was sufficient to start signing contracts and issuing the orders for construction to begin on the new refinery upgrades and expansions, there was an issue lurking in the background. Under pressure from the coal lobby in parliament, and recognising there could be great value if it worked, the government had setup the Falmouth Committee to report on the desirability of producing oil from coal. This was an important question as the UK had a fledging oil to coal industry, or more precisely it had a single facility that had miserably failed to fledge despite a great deal of patient support. A motley combination of industry and academia had been working on the process of turning coal into oil since the Great War and two decades of effort, a lot of research, and a very complex patent licensing deal with IG Farben and various British and international oil companies, had produce a process that worked. It just produced petrol that cost twice as much as any other source, so was limited to small scale pilot plants. However the Depression intervened and Imperial Chemical Industries (ICI) was able to cobble together an argument about import dependence, strategic flexibility and support for hard hit areas that convinced the National Government to support building a full scale plant. The support was not direct subsidy, instead it was exempting UK produced gasoline from paying fuel duty which in theory would make it competitive with conventional gasoline. Two years and six million pounds later the Billingham coal hydrogenation plant produced it's first shipment of synthetic gasoline from UK coal. While a technical triumph there was the small issue that, despite paying no fuel tax, the facility barely scrapped into the black and made nowhere near enough to even cover the cost of capital let alone show a useful profit. Despite this there were considerable calls to build additional plants, to produce it's 45 million gallons of petrol Billingham consumed 750,000tonnes of coal (which kept 2,000 miners employed) and employed another 2,000 staff in an economically depressed area. Given that was less than 2% of the UK's annual petrol consumption there was considerable scope to expand production, which would also considerably expand the effective subsidy of lost import duty which was not insignificant, Billingham alone was costing the exchequer £750,000 a year. Mere financial arguments were of precious little concern to the coal lobby, nor to the Labour Party who had naturally decided the problem was capitalism (in this case ICI) and if the facility was nationalised it would soon become profitable even after paying full duty. To these could be added the voices that argued that the technology was the problem and that Britain should abandon hydrogenation and use other methods to turn coal into oil. To investigate these concerns, or to make the matter go away for a while depending on your perspective, the Falmouth Committee had been setup and was due to report in the spring of 1938. The decisions made on 100 octane had somewhat pre-empted this, should the Committee come back and back domestic coal to oil then the matter would need to be re-considered. Despite this the Air Ministry pushed ahead, unwilling to wait another nine months for a decision that may not even be unfavourable. That this decision was recommended by the civil service, rather than having to be pushed through by an impatient minister, is testament to the changed attitude in Whitehall since the Abyssinian War. Whether this change was entirely for the positive was a different matter.

--

Notes:

Three weeks! Barely 20 days. This pace is terrifying.

This one is perhaps a bit over-detailed in places, but if nothing else I enjoyed finding out quite why 100 octane was so important, what it actually did to an engine and the many challenges behind sourcing and making the stuff. I have tried to steer clear of the worst of the chemistry though some did sneak through, there was no way to avoid it and still understand what was going on.

The RAF did find out about 100 octane that early and the boosts (or lack of them) that it gave to engines are OTL as is the whole rich mixture issue. Even well into the war this was an issue as the US just did not care about that as that didn't fit how they designed engines, as late as 1942/3 US fuel shipments had to be tested and occasionality 'doped' by the RAF (chucking in additives) so they worked as expected. Octane is a very bad way of defining fuel, the wartime bodge was defining the standard and rich response, so BAM100 became 100/130 octane (identical mix, new name) as it was 100 Octane standard and 130 octane rich. It's used out of legacy convenience, but the actual definitions of the fuel you see at the pump is a very complex series of curves and surfaces.

No.90 squadron was a guinea pig for 100 octane in 1937 and even as early as that the Air Ministry was stockpiling fuel, because production was limited. I skimmed over the production challenges, but pre-Ango-Iranian discovering Alkylation it was slow and expensive to make iso-octane and so 100 octane petrol, the fact it was discovered by accident is OTL of course. As per OTL it will take a while to get everything built and all planes flying on 100 octane, but things will be designed with it in mind from now on.

Now onto the changes, in OTL a couple of US refineries were upgraded and a US owned refinery in the East Indies also got a supply contract. Not in Butterfly because Anglo-American relations are a bit chilly, partly due to being on different sides of the Spanish Civil War and partly due to the Canton Island incident a few chapters back. Not hostile, just a greater awareness that US and British interests don't always align and plans should be made as such. So Abadan, which was OTL seen as a bit too far away from the UK, gets an upgrade instead because the Far Eastern war is seen as more likely and the Heysham refinery which was OTL started in 1939 gets pulled forward as well to make up the difference. The DEI sites are broadly unchanged, Rangoon is an important standard petrol and fuel oil site, but not really suitable for 100 octane, and Pelambang was OTL because it was just too big to ignore.

The Trinidad oil strike/riot is OTL, a complaint over stagnant wages that got out of hand very nastily and the Royal Navy was called in to reinforce the police. I have swapped the ships, a Canadian destroyer gets to come along instead of HMS Exeter and I imagine the Canadian politicians are a bit shaken up by it. The Royal Marines were just to stop the riots and didn't have to do any strike breaking, just support the out-numbered police while they restored order, the strikers even got most of their demands met in the end so it is fairly clean as these things go. A lot of Trinidad refined 100 octane will end up in Canada for the RCAF, so there is even a good strategic national interest reason for Canada to be actively supporting law and order in the Caribbean. But it is not what any of them expected and is very much a warning to Canadian politicians that having ships out on active patrol is not just friendly port visits and training exercises.

Finally the sad tale of British coal to oil efforts. It technically worked quite well, though it was limited and did require a lot of subsidy. As stated though it used a lot of coal so was really popular with the coal lobby and mining groups and of course the Labour Party who produced their own alternative Falmouth Committee Report, I believe because they didn't like what the real one said so decided to just make up their own version. We will probably end up looking at coal to oil again, because it touches so many important issues.

- 5

- 2

- 1